Cirmantech twisting machines and industrial equipment for rope making, cable production, and extrusion lines. We deliver high-performance, precision engineering solutions to transform the global textile and packaging industries.

Discover Our Solutions

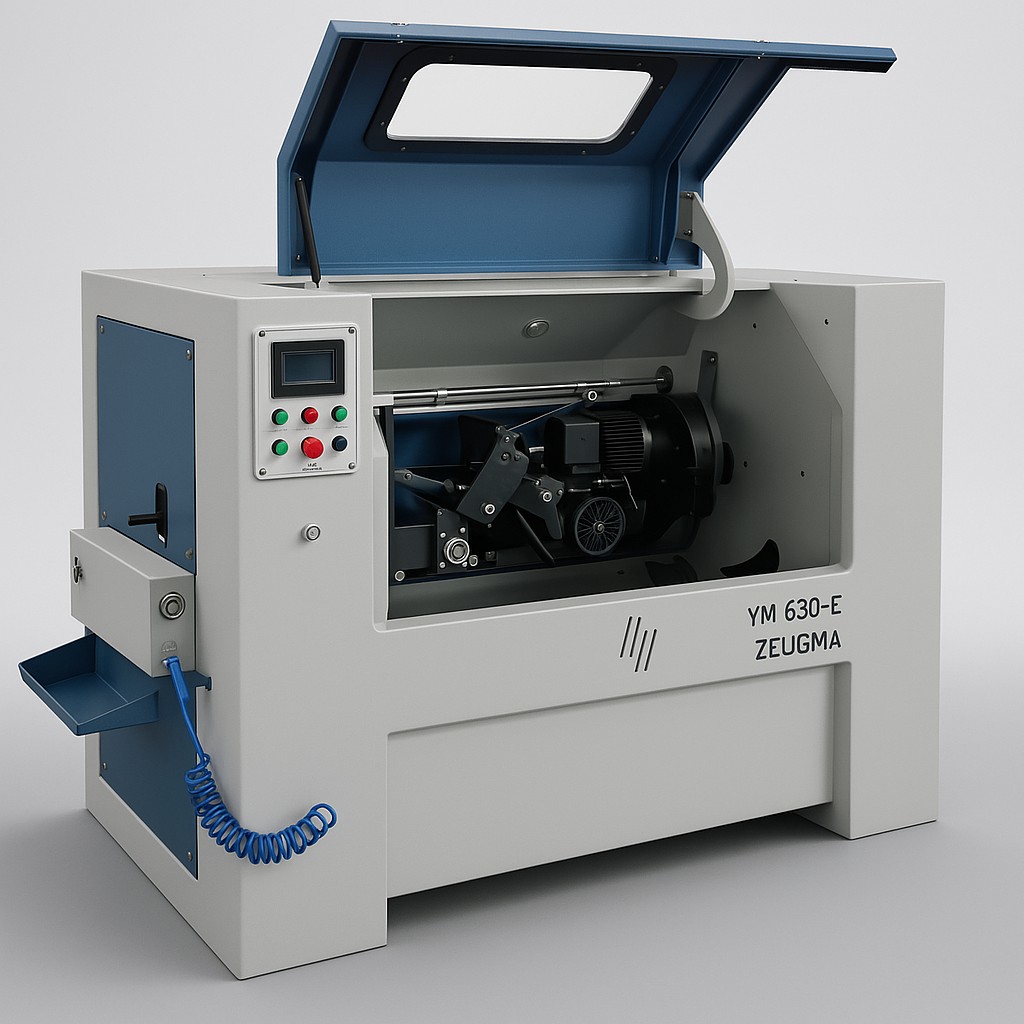

High-speed and reliable machines for industrial **twisting** operations on various materials and thicknesses.

Details

Precision systems for automatic and uniform winding of yarns exiting the **extrusion** line.

Details

Fully automatic bobbiner systems developed for material transfer and winding optimization.

Details

Optimized, durable, and efficient solutions for high-strength **rope production**.

Details

Accurate and high-capacity solutions for cable production and twisting of multi-core cables.

Details

Machines for producing high-quality synthetic or natural **fiber filaments** for concrete reinforcement.

Details

Turnkey machine solutions specifically designed for your business's unique needs.

Details

High-precision winding solutions developed for cable fillers and technical **yarns**.

DetailsCirmantech is an engineering-focused technology firm specializing in the design and production of high-performance **Cirmantech twisting machines, industrial machines, rope making, and extrusion equipment** required for rope, yarn, and cable manufacturing. Our Cirmantech industrial machines are trusted by manufacturers worldwide for their reliability and precision.

We combine a modern production approach with innovative solutions to meet the needs of industrial manufacturers globally. Cirmantech produces high-quality, reliable, and long-lasting machinery with advanced R&D capabilities and field experience. When you search for "Cirmantech twisting machine" or "Cirmantech industrial machines", you'll find our comprehensive range of professional equipment.

More InformationEvery machine we build is engineered specifically for your production requirements. We work closely with our clients to deliver solutions that fit their exact needs.

Tailored solutions designed around your production process

Work directly with our engineering team throughout your project

Quality craftsmanship with attention to every detail

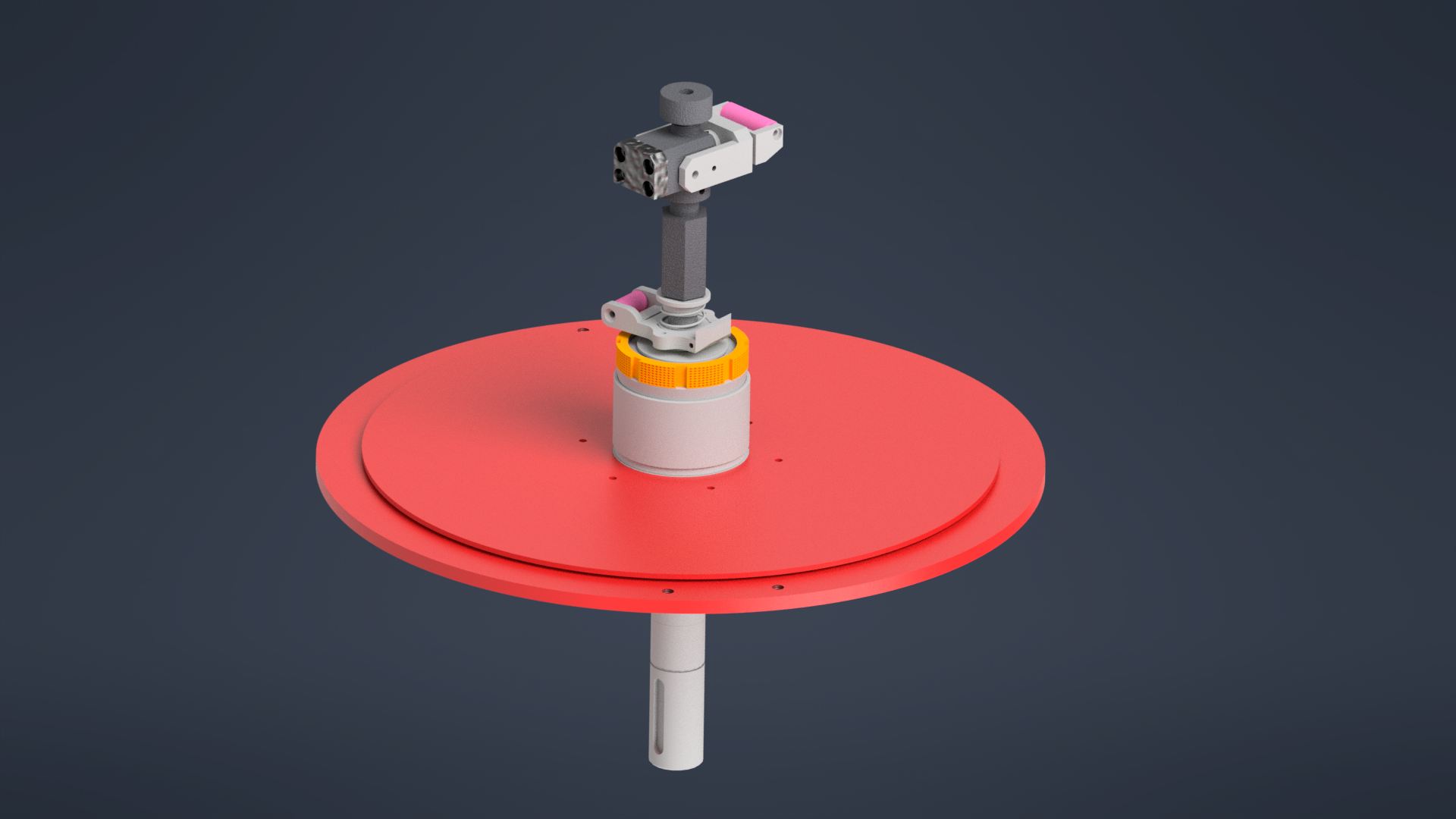

Kirman is a traditional yarn spinning tool, historically used to convert fibers like wool and cotton into yarn. This simple system, operating on the principle of a rotating spindle and weight, forms the basis of the modern **twisting machines** we produce at Cirmantech.

Our **twisting machines**, just like the kirman, join and twist fibers to create strong, uniform yarns. However, we achieve this on an industrial scale, with high-precision and automated modern machinery. In every machine we build, we carry a legacy that extends from tradition to the future.

Detailed InformationPlease do not hesitate to contact us for any kind of collaboration, project, or technical support requests.

Address: İlbade Mahallesi, Merkezefendi, Denizli, Türkiye

Phone: +90 554 806 8418 / +90 538 201 4761

Email: info@cirmantech.co

A twisting machine combines multiple strands of fiber, yarn, or wire by rotating them together to create stronger, more durable ropes or cables. Cirmantech twisting machines operate at speeds up to 3,000 RPM, feature servo-controlled torque, and PLC automation. We offer models from single-head laboratory units to 12-head industrial machines. Our equipment handles S and Z twist directions and processes yarns from 1,000 to 150,000 denier.

Our machines serve a wide range of industries: FIBC/Big Bag (sewing thread, webbing), Marine (ship ropes, fishing net yarns), Agriculture (baler twine, greenhouse rope), Construction (concrete fiber, safety rope), Telecommunications (cable filler), Automotive (wire harnesses, protective braiding), and Oil & Gas (high-strength pulling ropes).

Absolutely! Over 40% of our projects are custom-designed. Our process includes: 1) Needs analysis (material, capacity, space), 2) Free 3D concept design presentation, 3) Prototype or sample production, 4) Full production after approval. Our engineering team handles integration with existing lines, custom dimensions, and multi-language interfaces. WhatsApp: +90 554 806 8418

We offer extensive material compatibility: Synthetic (Polypropylene, Polyester, Nylon, HDPE), Natural (cotton, jute, sisal, hemp), Metal (steel wire, copper, aluminum, galvanized wire), Technical fibers (Aramid/Kevlar, glass fiber, carbon fiber, UHMWPE/Dyneema). We configure custom feeding systems and tension control for each material type.

Our 4-stage quality assurance system includes: 1) Material Selection: European-origin bearings, Siemens/Schneider electrical components. 2) Production Control: CNC machining, laser cutting, precision welding. 3) Factory Testing: Every machine undergoes loaded operation testing (min. 48 hours). 4) Customer Acceptance: Video-recorded test report presentation. Our 99.2% customer satisfaction rate since 2004 proves this commitment.

Our comprehensive after-sales support includes: 24/7 WhatsApp Support (instant technical assistance), Remote Access (online diagnostics via PLC), Spare Parts Stock (critical parts ready in Turkey, shipped within 48 hours), Field Service (on-site engineer visits on request), Maintenance Training (video guides and online sessions). Warranty: Standard 12 months, optional 24-month extension.

ROI varies by project: High-volume production: 12-18 months, Mid-sized operations: 18-24 months, Niche manufacturers: 24-36 months. Savings come from: 40-60% reduction in labor costs, 50-100% increase in production speed, 70% reduction in waste rate, 30% energy savings (servo models). Contact us for a free ROI analysis!

After order confirmation, production takes 8-16 weeks. Machines are tested at our factory with customer materials and shipped in working condition. On request, our installation team travels to your site for setup, calibration, and operator training. A dedicated project manager maintains weekly contact throughout the process.

Our servo motor models consume 30-40% less energy compared to traditional AC motor systems. Variable frequency drives ensure only the required power is used. Example: The YM630ES model saves approximately ~15,000 kWh annually compared to conventional alternatives.

We offer a wide capacity range: Laboratory (Twistlab-1): 10-50 kg/hour, Medium Capacity (YM430): 100-300 kg/hour, High Capacity (YM630ES): 500-2,000 kg/hour. From single-head to 12-head configurations, and 1,000 to 150,000 denier processing, we have solutions for every scale.

All industrial models are PLC-controlled (Siemens S7-1200/1500 or Schneider) with 7" touchscreen HMI panels. Features include: 100+ recipe storage, automatic speed and tension adjustment, production reporting and statistics, remote access (TeamViewer/VPN), and Industry 4.0/IoT integration options.

Yes, comprehensive training is included: Theory (machine principles, safety rules - 4 hours), Hands-on Practice (real production environment - 1-3 days), Maintenance (daily/weekly/monthly procedures), Video Library (QR-coded access, available 24/7), Certification (operator competency certificate upon completion).

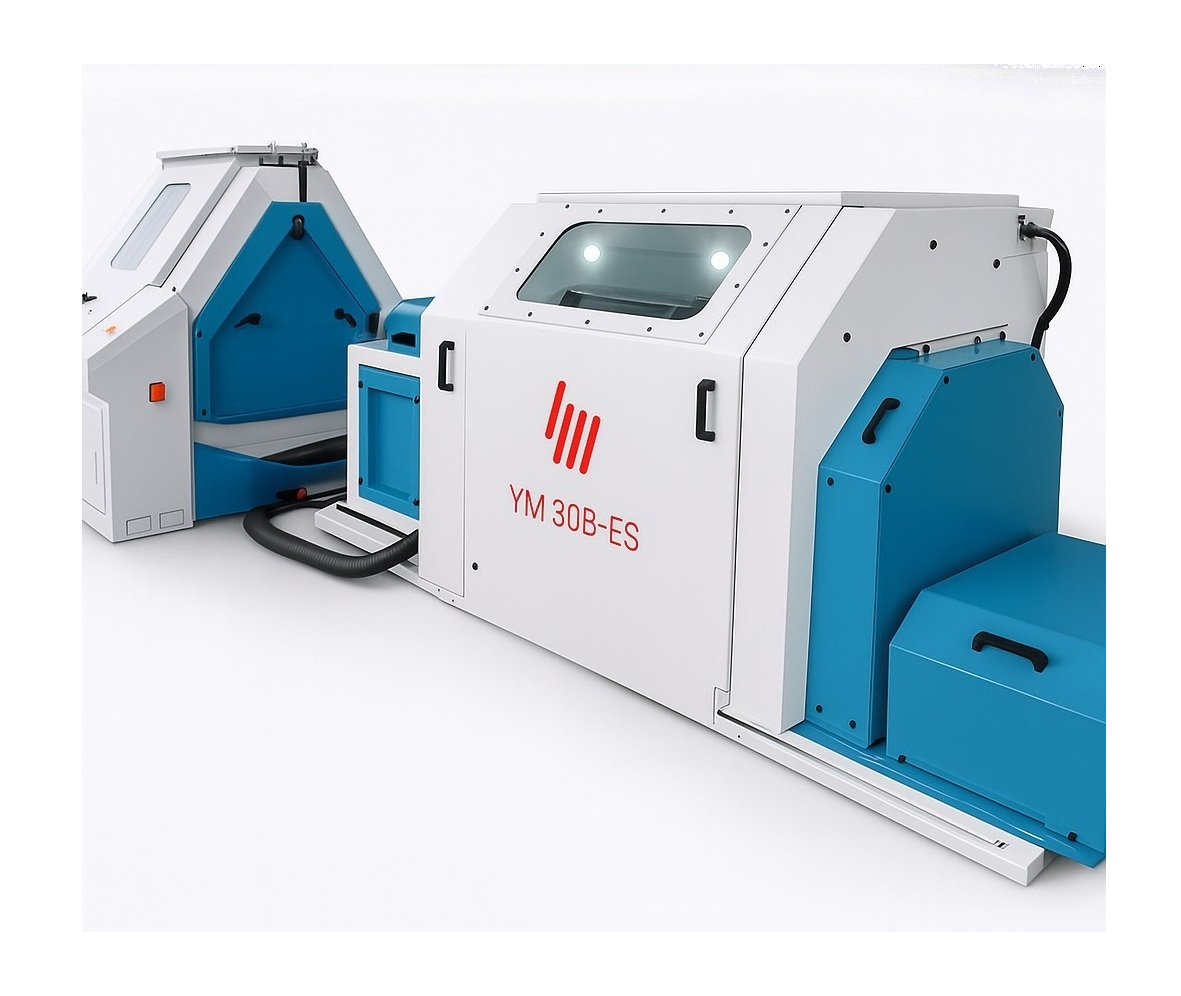

Absolutely. We design turnkey complete production lines: Extruder → Winder → Twisting Machine → Rope Maker. All systems operate with synchronized speed control and single-panel management. The modular design allows future capacity expansion. We also integrate with your existing extruder lines.

Since 2004, we've exported machines to over 60 countries: Middle East (Saudi Arabia, UAE, Egypt, Jordan), Africa (Nigeria, Kenya, Ethiopia, South Africa), Europe (Spain, Italy, Greece, Romania), Central Asia (Kazakhstan, Uzbekistan, Turkmenistan), South America (Brazil, Argentina, Chile). We provide country-specific voltage adaptation, language support, and local service network connections.